The Benefits of a Tightly Integrated Supply Chain System

Why Tightly Integrated Supply Chain System?

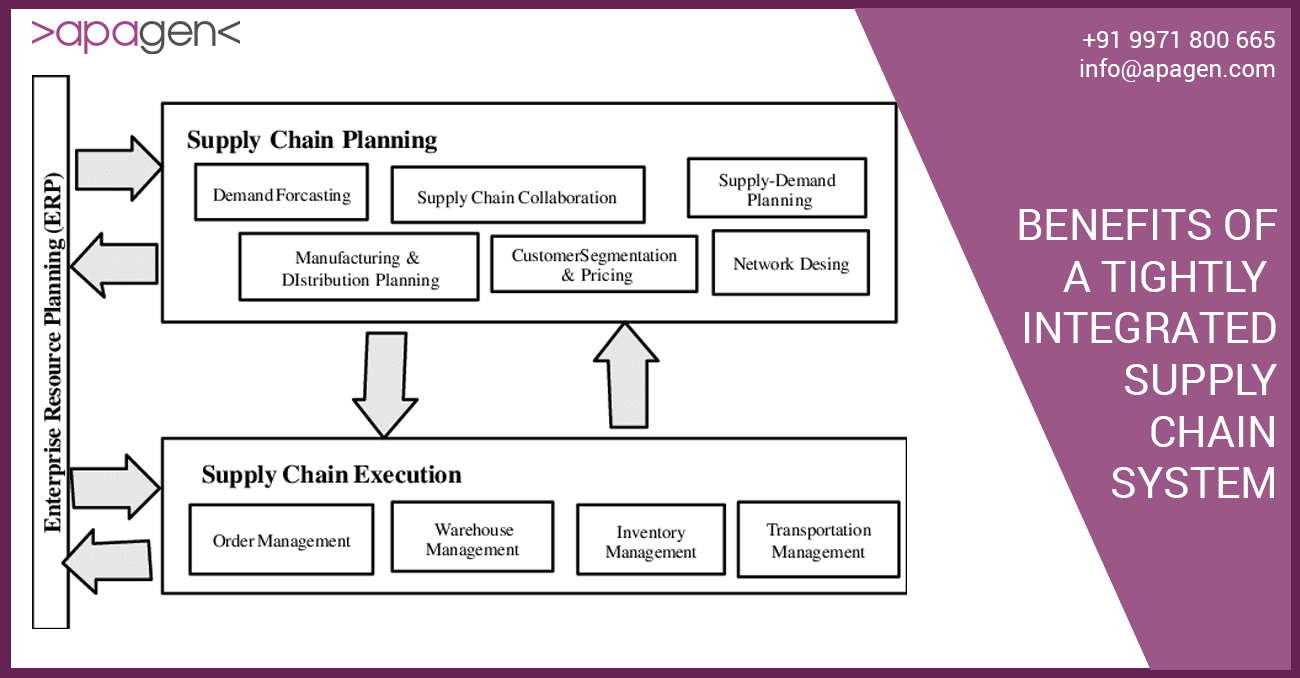

A tightly built-in supply chain for a small or massive enterprise is a community of companies and contractors that provide uncooked materials, transportation, manufacturing, distribution, warehousing and retailing services. Businesses depend on efficient supply chains to offer an excessive level of customer support, whereas assembly sales and revenue targets. Information technologies, including ERP systems, are at the core of the Integrated Supply Chain System.

Benefits

Flexibility

Tight supply chain integration provides administration operational flexibility to respond quickly to external occasions, such as the actions of opponents and modifications in customer demand. Companies can collect intelligence via their supply chains, which permits them to be usually aware of what their competitors are planning months upfront. For instance, if a competitor launches a new product, an electronics producer may leverage its Integrated Supply Chain System to supply the elements, activate an advertising plan and rush a prototype from the design stage to the launch stage in a few weeks.

Inventory Management

Built-in supply chains enhance stock administration, which implies fewer overstocked and understocked situations. Overstocking might lead to larger storage prices and product obsolescence, whereas understocking may imply shedding customers to opponents. Tight integration signifies that retailers can shortly modify their stock orders weeks or months upfront of anticipated modifications in buyer demand to make sure that the correct quantity of inventory is available. Speed is important in world supply chains because uncooked materials and completed items are often transported over lengthy distances. Tightly built-in supply chains additionally facilitate just-in-time manufacturing, wherein firms assemble and manufacture products as the orders are available.

Profit Margins

Operating flexibility and tight inventory administration leads to a decrease in value structure, which leads to larger revenue margins. By responding quickly to modifications within the competitive and buyer environments, small companies are capable of remain aggressive and keep or develop their high and backside strains. Tight integration offers firms with visibility not solely into their very own operations but additionally into their suppliers’ operations, which permits for collaborations on lowering prices and driving margins.

Considerations

Tightly integrated system supply chains system can function early warning systems solutions. For instance, if a provider is experiencing money flow issues, clients will discover out quickly and they can begin making different preparations. Some clients might step in and loan the supplier some working capital in order that they will proceed to work. Supply chain integration usually includes upfront prices and disruptions in operations as people are skilled in new information systems.

No Comments